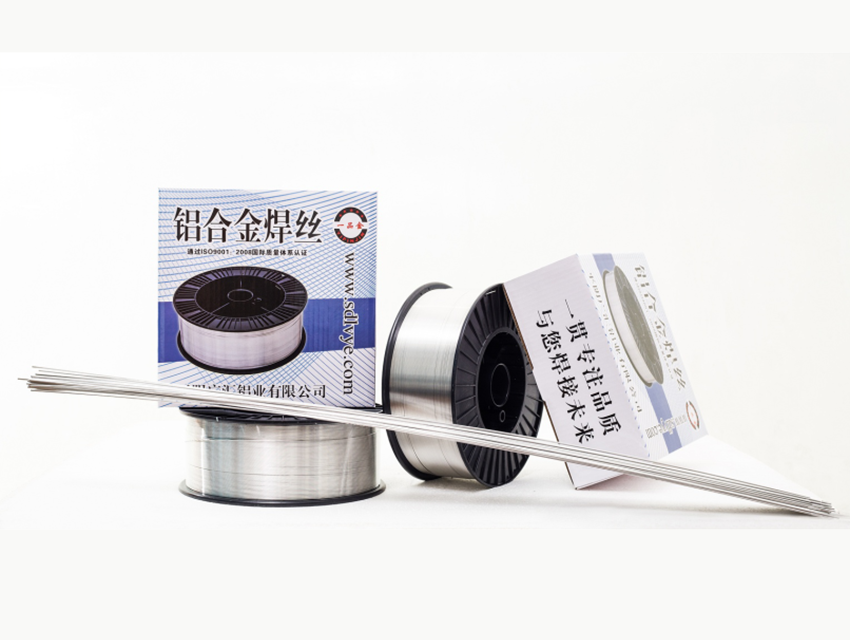

ER5183 aluminum welding wire

ER5183

aluminum

spool - drum

China

AWS A5.10 ER5183

international standard

ISO,CE

accept ODM also

0.5kg / 2kg / 7kg

7-15 Days

1000 KGS

600 Tons per Month

0.8mm / 0.9mm / 1.0mm / 1.2mm/ 1.6mm/ 2.0mm

025 / 030 / 035 / 040 / 045 / 0.030

ER5183 aluminum welding wire Features

ER5183 aluminum/magnesium GMAW (MIG) welding alloy

Designed for welding heat treatable base alloys, specifically 6XXX series alloys

Lower melting point and more fluidity than 5XXX series filler alloys

Low sensitivity to weld cracking with 6XXX series base alloys

Suitable for sustained elevated temperature service, i.e. above 150°F (65°C)

All position, except vertical down welding

Gray (post anodized) color

ER5183 aluminum welding wire Specifications

Liquidus 1175°F (640°C) (as welded 5083/5654 base plate)

Solidus 1060°F (575°C) (as welded 5083/5654 base plate)

Tensile Strength 39,000 psi (as welded 5083/5654 base plate)

Yield Strength 19,000 psi (as welded 5083/5654 base plate)

Density 0.096 lbs./cu.in. (as welded 5083/5654 base plate)

Elongation (A) 15 - 25% (as welded 5083/5654 base plate)

ER5183 aluminum welding wire video

![]() 焊丝制作流程.mp4

焊丝制作流程.mp4

ER5183 aluminum welding wire Factory Show

ER5183 aluminum welding wire Application

It is also used in the welding of aluminum, silicon, magnesium, aluminum, zinc and magnesium alloy and the repair welding of aluminum and magnesium alloy castings.

ER5183 aluminum welding wire Certification

ER5183 aluminum welding wire WHAT YOU GET

ER5183 Aluminium MIG Welding Wire

Choose Your MIG Wire Size in mm: 0.8mm / 0.9mm / 1.0mm / 1.2mm/ 1.6mm/ 2.0mm

Choose Your MIG Wire Size in inch: 0.030 / 0.035 / 0.040 / 0.045/ 0.063/ 0.079 / 3/16 - 3/64

Choose Your Wire Spool Weight(Package): 0.5kg / 2kg / 7kg

Choose Your TIG Wire Size: 1.2mm/ 1.6mm/ 2.0mm/ 2.4mm/ 3.2mm/ 4.0mm/ 5.0mm

Choose Your Wire tube Weight(Package): 2kg / 5kg / 10kg / 1LB / 2LB / 4.5LB / 15.5LB / 20LB

ER5183 aluminum welding wire welding knowledge

gasless aluminum welding wire Winding Requirements

Filler metal on spools and in coils without support shall be wound so that kinks, waves, sharp bends, overlapping, wedging are not encountered, leaving the filler metal free to unwind without restriction. The outside end of the filler metal (the end with which welding is to begin) shall be identified so it can be located readily and shall be fastened to avoid unwinding.

The outermost layer of spooled electrode or spooled rod shall not be closer than 1/8 in. [3 mm] to the outside diameter of the flanges.

The cast and helix of filler metal on spools shall be such that the filler metal will feed in an uninterrupted manner in automatic and semiautomatic equipment.

ER5183 aluminum welding wire FAQ

mig welding aluminium wire 10 famous brand are which factory?

1:sanzhong, 2:giant, 3:safra, 4:Hobart, 5:SAF, 6:ALCOTEC, 7:INDALCO, 8:GULF, 9:Oxford, 10:harris

aluminum mig wire supplier and factories or wholesale locates in such countries like?

China,America,Brazil,England,Russia,Poland,India,Pakistan,NewZealand,Korea,Australia,Dubai,Turkey,Indonesia,UAE.

aluminium bronze welding wire can filler feed how many welders?1060,1070,1080,1350,1100,2014,2036,2219,3003,ALCLAD3003,3004,ALCLAD3004,5005,5050,5052,5652,5083,5456,5086,5056,

511.0,512.0,513.0,514.0,5154,5254,535.0,5454,6005,6063,,6101,6151,6201,6351,6951,6061,6070,7005,7021,7039,7046,710.0,

711.0,7146,413.0,443.0,444.0,356.0,A356.0,A357.0,359.0,319.0,333.0,354.0,355.0,C355.0,380.0

How to choose a suitable gasless mig aluminium welding wire?or what type of filler wire is best for tig welding for aluminium?

General Notes:

1.Service conditions such as immersion in fresh or salt water,exposure to specific chemicals,or asustained high temperature,aluminium welding wire for high heat(over 150F [66℃)may limit the choice of filler metals welding wire aluminium, aluminium welding wire for mig Filler metals ER5183,ER5356 welding rod,ER5556 are not recommended for sustained elevated temperature service.

2.aluminium mig welding wire recommendations in this table apply to gas shielded arc welding processes.For oxyfuel gas welding,only ER1188,ER1100,ER4043,ER4047,ER4145 filler metals are ordinarily used and aluminium welding wire specification.

3.Where no filler metal is listed,aluminum alloy welding wire ,the base metal combination is not recommended for welding

aluminium welding wire gasless.

Notes:

a. ER4145 may be used for some applications to some aluminum alloy welding wire.

b. ER4047 may be used for some applications to some flux cored aluminium welding wire.

c. ER4043 may be used for some applications to some aluminium magnesium welding wire.

d. ER5183,ER5356,or ER5556 may be used to some aluminium welding wire grades.

e. ER2319 may be used for some applications.It can supply high strength when the weldment is postweld solution heat treated and aged.

f. alum.welding wire ER5183,ER5356,ER5554,ER5556,and ER5654 may be used In some cases:(1) improved color match afer anodizing treatment,(2) highest weld ductility (3) higher weld strength.ER5554 is suitable for sustained elevated temperature service.

g. alum welding wire ER4643 will provide higher strength in 1/2 in.[12mm]and thicker groove welds in 6XXX base alloys when postweld solution heat treated and aged.

h. flux core aluminum wire Filler metal with the same analysis as the base metal is sometimes used.The following wrought filler metals possess the same chemical composition limits as cast filler alloys: ER4009 and r4009 as R-C355.0;ER4010 and R4010 as R-A356.0; R4011 as R-A357.0.

i. Mig welding aluminum wire ,Base metal alloys 5254 and 5652 are used for hydrogen peroxide service.ER5654 filler metal is used for welding both alloys for service temperatures below 150F [66°℃].

j. ER1100 may be used for some applications in wire feed welding aluminum.