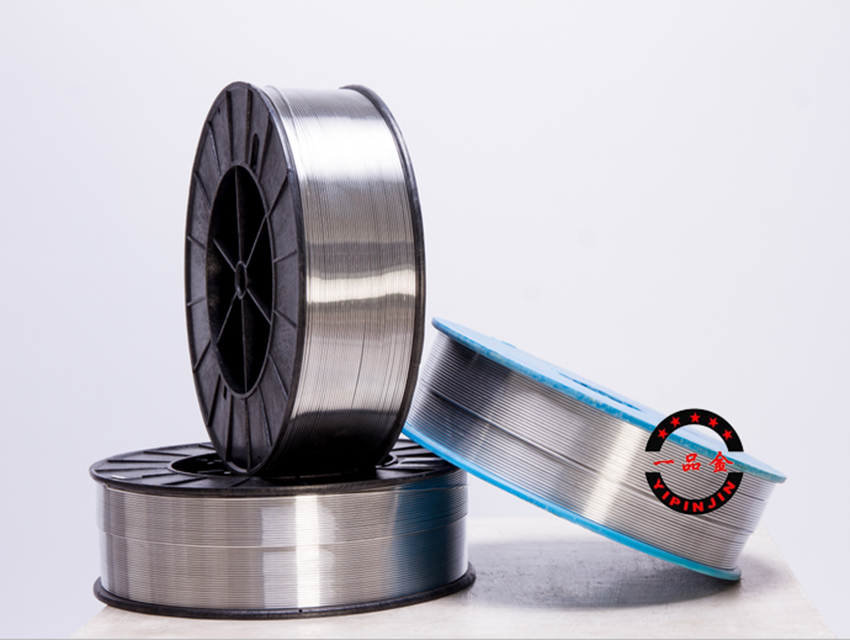

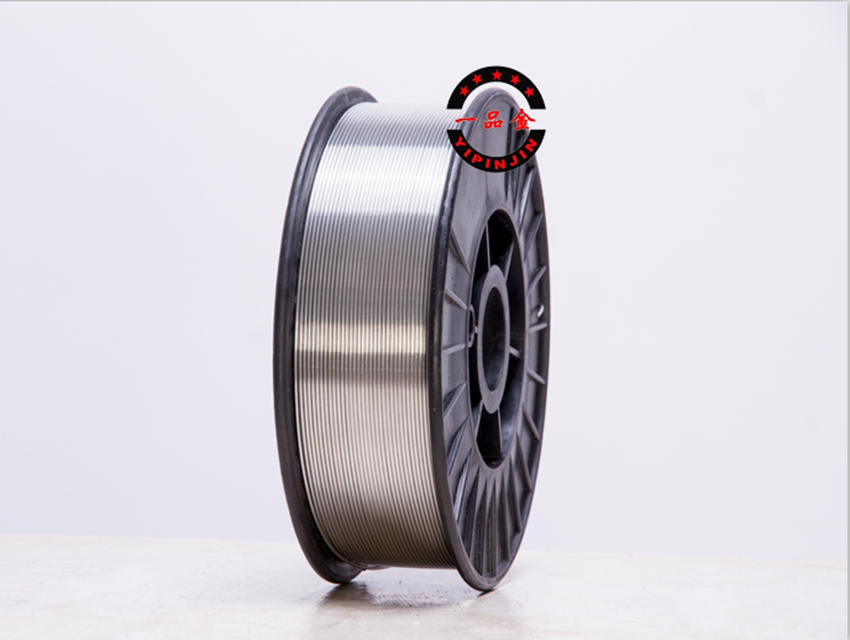

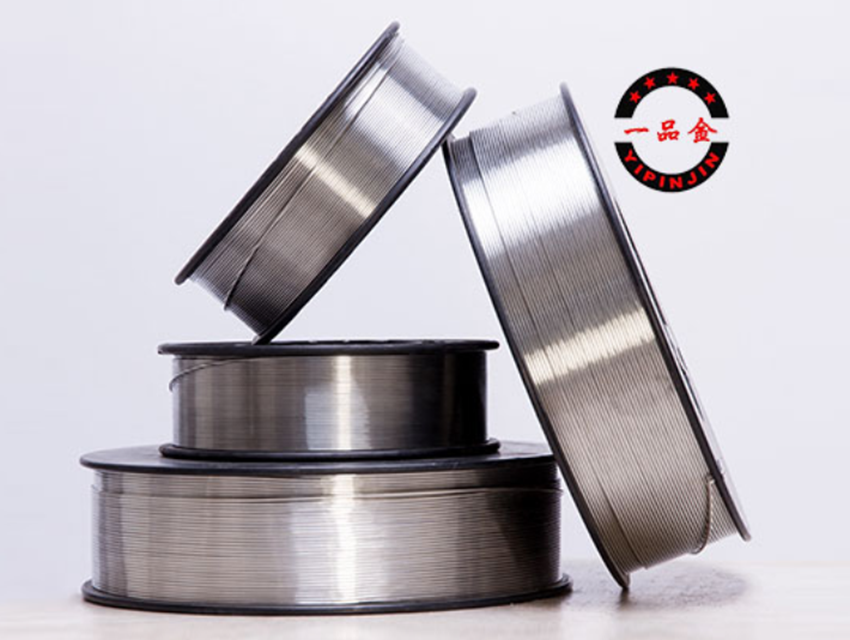

Sprayed aluminum wire

Thermal spraying technology is a technology that has developed rapidly in surface engineering in recent years and plays an important role in the field of surface engineering. The so-called thermal spraying is to use a heat source (such as flame, arc, plasma arc, etc.) to heat the metal, non-metal or composite material to a molten or semi-melted state, and then atomize and accelerate the compressed air to form many tiny droplets, and The high-speed is directed at the substrate, and the droplets on the surface of the substrate collide into a flat shape and are bonded to each other to form a good bond with the substrate. The coating cools rapidly and builds up, eventually forming a layered coating!

1. Purity: 99.8%

2. Specifications: 0.6mm~4.2mm

3. Packing: 15~20kg/bundle, 6~7.5kg/axis.

4, aluminum wire appearance is smooth and bright, no broken wire, no oil and burrs, no scratches and knots.

5. The raw materials are all made of high quality aluminum ingots (including more than 99.7% aluminum), strictly in accordance with the national standard GB/T3955-2009. The company adopts advanced automatic computer control equipment, which not only strictly controls the quality of the products, but also reduces the quality. The cost of production.

6, the product is widely used in steel structure surface anti-corrosion, container, bridge, derrick, storage tank, power tower, pole, capacitor, metal bracket, ductile iron pipe, traffic equipment and other surface coating anti-corrosion in

Catalog download: